Content Map

Benefits of Tube Inserts

DOI 10.1615/hedhme.a.000382

3.21.2 Benefits of tube inserts

John M. Ritchie and Peter Droegemueller

The previous section outlines the design objectives that may be required when implementing tube inserts. The use of tube inserts as a “process intensification” device makes them widely accepted in the use of area reduction, and as such most practical design examples will offer comparisons of the heat transfer area reduction (and often reduction in number of shells) resulting from the use of a particular enhancement technique. Whilst this section considers area reduction in most detail, due primarily to the fact that it is a simple and accessible measure of insert performance, the other principal design objectives (which are as appropriate to retrofitting as they are to design from scratch) should be considered as a benefit of tubeside heat transfer enhancement. Apart from those already identified, the use of tubeside inserts may result in other benefits, including improved plant control and fouling mitigation, both of which shall be considered in this section.

A. Determining performance in terms of area reduction

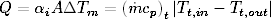

It has been shown analytically that performance may be defined in terms of heat transfer area reduction as follows (ESDU, 1998). Taking the rate of heat transfer in terms of tubeside conditions, thus:

|

(1) |

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here