Navigation by alphabet

A B C D E F G H I J K L M N O P Q R S T U V W X Y ZIndex

Fluidized Beds

DOI 10.1615/hedhme.a.000148

2.2 SINGLE-PHASE FLUID FLOW

2.2.6 Fluidized beds

K. E. Wirth

A. Fluidization principle

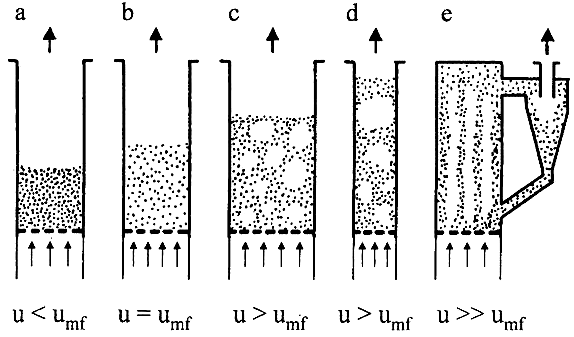

(a) Types of fluidization

In a fluidized bed the solid particles are carried by an up-flowing fluid (gas or liquid). The weight of the particles is balanced by the force which is exerted by the fluid flow on the particles. The bed as a whole shows a liquid-like behavior.

At low flow rate the fluid percolates the voids of the solids bed without changing the bed structure. The void fraction of the bed ε, i.e. the bed porosity, does not depend on the fluid flow rate, and thus remains constant. This operating mode is called fixed bed (Figure 1a). The particles are resting on a plate which is only permeable to the gas. An increase in the flow rate, and thereby in the forces exerted by the fluid on the solid material, results in individual particles beginning to move within narrowly bounded regions, whereas the majority of the particles remain in permanent contact as a fixed bed. With a further increase in the throughput of fluid, a situation is reached where the particles are not in permanent contact with one another and are supported by the fluid. In this state, the fluid pressure drop measured between two horizontal reference planes is in equilibrium with the weight, per unit bed cross sectional area of the solid and fluid contained between these planes. The bed has now attained fluidization (see Figure 1b) and is characterized by the voidage εmf and the height hmf. The corresponding superficial gas velocity is called minimum fluidization velocity umf.

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here