Navigation by alphabet

A B C D E F G H I J K L M N O P Q R S T U V W X Y ZIndex

Film Condensation of Pure Vapour

DOI 10.1615/hedhme.a.000185

2.6 CONDENSATION

2.6.2 Film Condensation of Pure Vapour

J. M. McNaught and D. Butterworth

A. Introduction

The various resistances to heat transfer during condensation are described in Section 184B. In condensation of a pure vapour, the main resistance is that of the film of condensate which forms on the cooled surface. With a laminar condensate film, heat transfer is by conduction so a thin film will give a lower resistance and therefore a higher heat transfer coefficient than a thick film. Turbulence in the film acts to increase the heat transfer coefficient. Vapour shear has the effect of thinning the film, inducing turbulence, and therefore of increasing the heat transfer coefficient. Other factors which affect the condensate heat transfer coefficient are waves on the film surface, droplet entrainment and deposition, condensate splashing, and condensate subcooling.

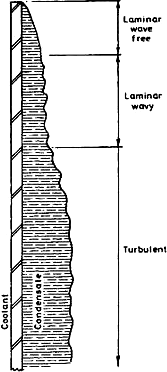

Section B provides methods for heat transfer with condensation on a vertical surface, which in a heat exchanger would normally be a vertical tube. Figure 1 illustrates condensation on a vertical surface when the vapour is considered to be stagnant and there is therefore no effect of vapour shear on the condensate film. The condensate drains vertically downwards under gravity, with a flowrate steadily increasing from zero at the top. At the very low film Reynolds numbers at the top of the surface the condensate flow is laminar and wave-free. At some point down the tube surface a transition occurs where waves form on the condensate film. This transition is due to instabilities at the vapour-liquid interface, and it can be characterised by the film Reynolds number. At a much higher Reynolds number there is a transition from laminar-type flow to turbulent flow. In the laminar region the heat transfer coefficient decreases as the Reynolds number increases. The rate of decrease becomes smaller in the laminar-wavy region because of the disturbances caused by the waves. In the turbulent region the higher effective viscosity causes the film to become thicker. However the overall effect in the turbulent region is that the heat transfer coefficient increases as the Reynolds number increases. This is because the increased convection due to turbulence more than compensates for the thickening film. Liquid metals can behave differently, as shown in Section F.

The effect of a downwards vapour velocity is to increase the heat transfer coefficient by both thinning the film and inducing turbulence (see Section B). An upward vapour velocity will tend to have the opposite effect. However a phenomenon known as flooding occurs before vapour velocities are high enough to affect heat transfer significantly. This phenomenon is where the upwards vapour flow prevents the condensate from draining from the bottom of the surface. This is discussed in Section B(e).

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here