Navigation by alphabet

A B C D E F G H I J K L M N O P Q R S T U V W X Y ZIndex

General Introduction

DOI 10.1615/hedhme.a.000223

2.12.1 General introduction

Jonas Gylys

A. Introduction

In many technological processes, which deal with heat and mass transfer, two-phase flows consisting of liquid and gas are exploited. These two phases may be in different states, which depend on the hydrodynamic state of whole the system.

The foam state is one of the possible forms of gas- liquid system. The foam is generated when gas and liquid comes into contact.

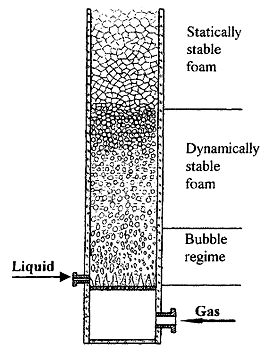

Let us consider the structure of a vertical upward two-phase flow generated from a detergent solution (Figure 1). A structure of this two-phase system varies depending on the height of the flow channel. Directly on the plate exists the bubble or so-called barbotage regime. Near the plate a regime of dynamically stable foam (DSF) exists, which consists of a turbulent mixture of the gas and liquid flows. Dynamically stable or turbulent foam is a very unstable two-phase system. It exists only with gas feed to the distributor plate. If the delivery of gas stops, the turbulent foam immediately decays into pure liquid and gas (in the case where a foam is generated from a pure liquid) or in the case of the detergent solution it turns into the statically stable foam (SSF). For pure liquid only dynamically stable foam can be generated. From a detergent solution, both dynamically stable and statically stable foams can be generated. Statically stable foam (cellular foam) consists of gas bubbles, which have the shape of regular polygons, separated each from other by the thin liquid films. Even in the absence of gas delivery, SSF can exist for quite long periods of time (from seconds to days or years).

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here