Content Map

Headers, Nozzles and Turnarounds

DOI 10.1615/hedhme.a.000149

2.2.7 Headers, nozzles, and turnarounds

J. A. R. Henry

Introduction

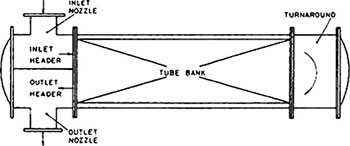

The prime purpose of nozzles, headers, and turnarounds is to distribute fluid through a heal exchanger matrix, as shown in Figure 1 for a typical case.

The indirect purpose of these components, in common with the others making up the structure, is lo contain the process fluids, which may be under high pressure. Hence, although their prime function is to direct and distribute flow, it is often found that their design is dictated by strength, cheapness, or ease of manufacture, rather than by considerations of fluid dynamics. In many instances this approach results in poor distribution of the fluid within the heat exchanger.

Poor distribution may or may not result in unsatisfactory performance, which in the past has usually been of secondary importance. However, with the increasing cost of energy and materials, it is desirable to utilize equipment to maximum efficiency during its lifetime. This requires a balanced performance, one aspect of which is achieving more uniform flow distribution. Associated with this is the need to predict pressure drop with some accuracy.

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here