Content Map

Furnace Type

DOI 10.1615/hedhme.a.015514

3.11 FURNACES AND COMBUSTION CHAMBERS

3.11.3 Furnace Type

C. E. Baukal, J. M. Rhine, and J. S. Truelove

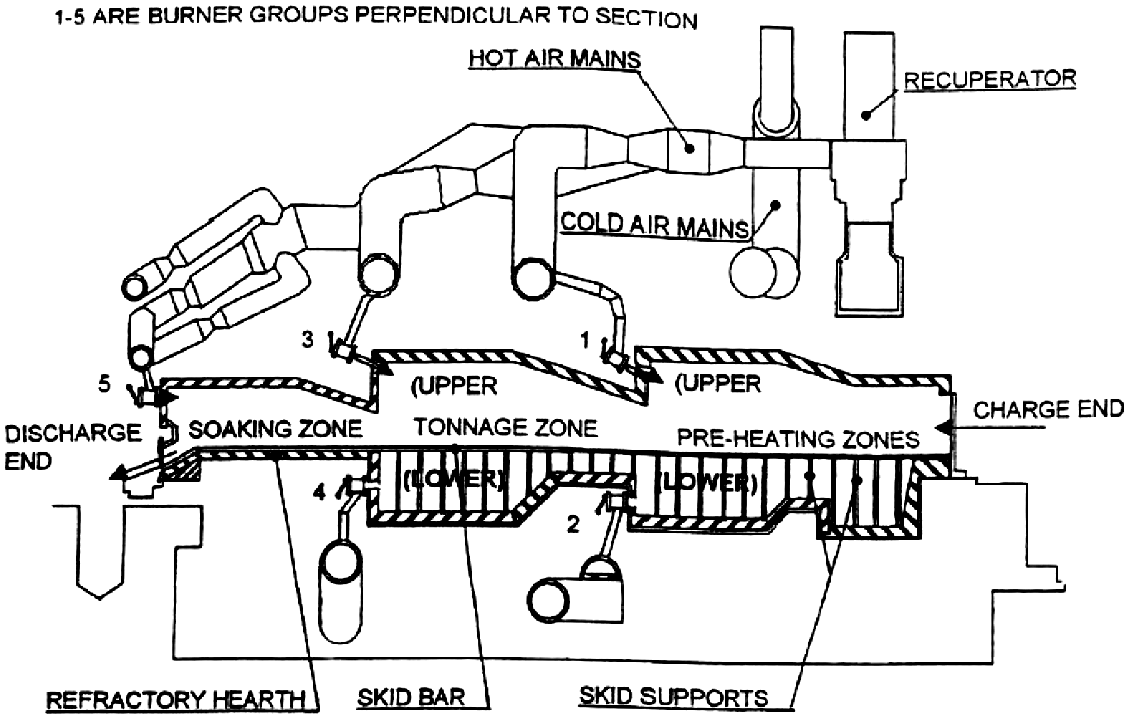

In the chemical and manufacturing industry, there are numerous applications of furnaces and kilns, many of which utilize fossil fuels as the source of heat transfer. These furnaces and kilns are basically refractory boxes in which the material is heated to a predetermined temperature from an open flame. Often, this will be to a comparatively high temperature ( > 1,500 °C or > 2,700 °F) depending on the application (see Table 3). Thus, in most cases the main mode of heat transfer will be by radiation and, hence, the theoretical techniques described in the following sections are equally applicable to these applications. The refractory walls considerably reduce the heat loss to the surrounding, although the final external structure will be a steel casing (Figure 24).

Table 3 Approximate operating temperatures of industrial furnaces (Courtesy: University of Glamorgan, UK)

| Material | Process application | Typical operating temperatures (°C) |

|---|---|---|

| Steel slabs | Reheating for hot working | 1,200–1,300 |

| Steel sheet | Bright annealing | 680–730 |

| Steel | Tempering | 450–700 |

| Aluminum | Melting | 750–850 |

| Aluminum | Forging | 400–500 |

| Aluminum alloys | Heat treatment | 150–550 |

| Copper | Melting | 1,150–1,350 |

| Cement | Kiln firing | 1,530–1,650 |

| Ceramics including sanitary ware | Firing | 1,200–1,300 |

| Glass | Melting | 1,450–1,590 |

There are, however, some important differences to conventional process heaters. As well as heat being transferred directly from the flame, the load receives significant heat by radiation from the inner wall surface, which will be at a higher temperature than the load. Also, depending on the fuel type and the furnace configuration, convective heat transfer can also be significant.

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here