Fluidised beds

DOI 10.1615/hedhme.a.000203

2.8 GAS-SOLID SYSTEMS

2.8.4 Fluidized beds

H. Martin

A. Introduction

The overall fluid dynamic behavior and the local flow Structure of gas-solid fluidized beds are outlined in Section 148. Section 172 deals with fluid-to-particle (i.e., single-phase) convective heat transfer. More detailed descriptions of the basic principles and technical applications of fluidization may be found, e.g., in the books by Davidson et al. (1985), Kunii and Levenspiel (1969), Zabrodsky (1966), and Botterill (1975).

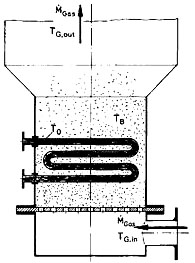

Heat exchanger elements such as plates, tubes, coils, or bundles of tubes are frequently used directly inside a flutdized-bed reactor, as shown schematically in Figure 1, or in a separate fluid bed heat exchanger Reh et al. (1983) in order to remove or add the appropriate amount of thermal energy to keep the gas-solid system at a desired level of temperature.

The problem of heat transfer to fluidized beds of solid particles was treated for the first time in Mickley and Trilling’s pioneering paper in (1949). Since then, many interesting facts about heat transfer between gas fluidized beds of solid particles and heat exchanger surfaces have been discovered through experimental work. As an example, Figure 2 shows a typical result from experiments carried out by Wunder and Mersmann (1979) in a test setup similar to the one used by Mickley and Trilling about 30 years previously.

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here