Content Map

Suction line heat exchangers

DOI 10.1615/hedhme.a.000402

3.26.6 Suction line heat exchangers

J. R. Barbosa, Jr. and C. J. L. Hermes

A. Liquid to suction line heat exchanger

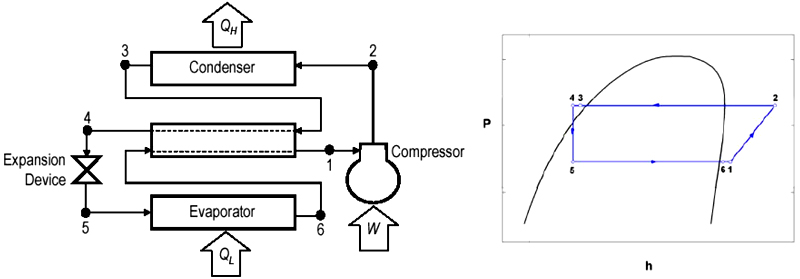

Some refrigeration systems, particularly those operating at low evaporating temperatures (e.g., household refrigerators and freezers), employ an additional heat exchanger to transfer heat from the liquid going to the expansion device to the vapour going to the compressor, as illustrated in Figure 1. The internal heat exchanger, also called liquid to suction line heat exchanger (LL/SL HX), increases the refrigerating effect by reducing the vapour-quality at the evaporator inlet as heat is removed from the liquid leaving the condenser (enthalpy difference between points 3 and 4 in Figure 1). Although the heat transfer between the refrigerant in the expansion device and the suction line increases the refrigeration capacity per unit mass flow rate (h6 – h4 > h6 – h3), it also results in the compression being pushed farther out into the superheated vapour region, where the compressor inlet aspires a higher specific volume gas (that results in a decrease in mass flow rate) and the compressor work per unit mass (h2 – h1) is greater. The system COP, on the other hand, may increase or not depending on the refrigerant. The COP decreases for ammonia and R-22, but it increases for R-134a and R-290, for example. More details can be found in Gosney (1982).

Figure 1 Schematic representation of a refrigeration cycle with a liquid to suction line heat exchanger

Liquid to suction line heat exchangers are usually assembled according to a double-pipe counterflow arrangement (see Section 3.2). The amount of heat to be transferred per unit of mass is given by the following energy balance,

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here