Content Map

Selection of condenser types

DOI 10.1615/hedhme.a.000261

3.4.2 Selection of condenser types

A. C. Mueller

The art of condenser design involves evaluation of the specified process conditions, together with other potential physical, thermal, and economic limits in order to select potential types of condensers, which are then subjected to rating calculations to determine the sire or capacity. The several designs are then evaluated to determine the best economic choice. This design must meet certain basic requirements: (1) it must be operable over a range of conditions including design point; (2) it must be capable of economic fabrications; and (3) it must meet other specific limitations that may be imposed, such as size, weight, or maintenance.

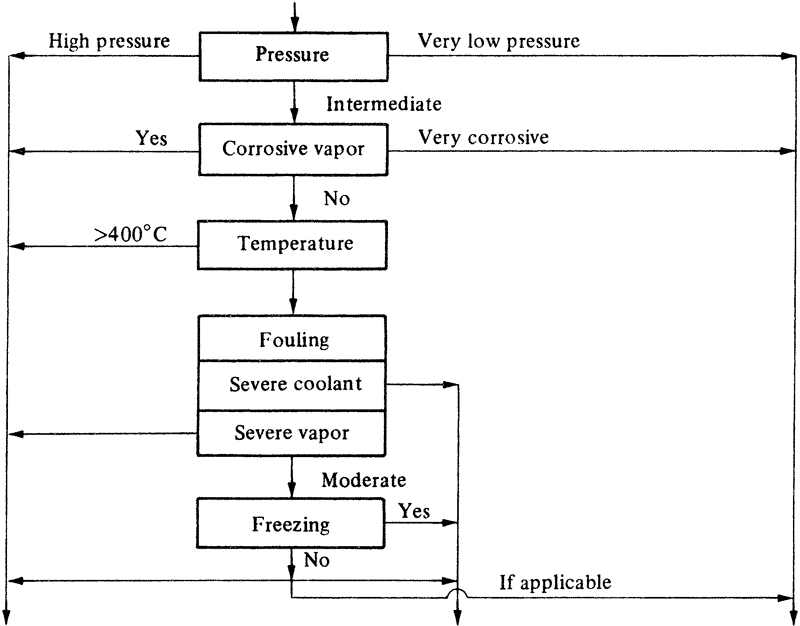

The selection of suitable types of condensers involves the consideration of numerous conflicting requirements. The principal factors involved in selecting a suitable type of condenser depends on whether condensation is total or partial, whether the vapors are single or multicomponent, and whether some components are noncondensable. The coolant can impose further restrictions, particularly if it vaporizes. The additional requirement for condensate subcooling within the condenser also influences the condenser type. The various classes of condensation are indicated in Figure 1 and Figure 2. These charts are for a preliminary selection of condenser types to be evaluated. In them 3 preliminary screening is done via the line network to separate the unusual conditions that may limit the choice of types. A secondary table then gives opinions on the applicability and predictability of the various types of condensers. Here a careful examination of secondary factors will further narrow the choice of condenser types. There are coded numbers for various classes or individual types of condensers that pertain to special comments, advantages, or disadvantages. These comments will also aid in making a decision. There are two charts, one for total condensation and one for partial condensation.

|

* See comments for Carts 1 and 2. † Acceptability: G = good, F = fair, P = poor, X = not applicable or not recommended. Predictability: ○ = average ∼ 25%, ◒ = fair < 50%, ● = poor 50 + %, ⊗ = no method or not recommended. |

|||||||||||

| Tube-side condensation 4, 11 * | Shell-side condensation 2, 3, 12 | Direct contact condensation 14 |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Horisontal 8 | Vertical 13 | Horisontal 1 | Vertical 5, 10 |

||||||||

| Downflow 7 | Upnflow 6, 9 | Cross "X" 10 | Baffled | Downflow | Upflow | ||||||

| Single-component vapor | G † ○ | G ○ | F ◒ | G ◒ | G ◒ | G ◒ | G ● | G ◒ |

|||

| Multicomponent vapor | F ◒ | G ◒ | F ● | G ◒ | G ◒ 18 | G ● | F ● | P ● |

|||

| Subcooled condensate | P ⊗ | G ○ | X ⊗ | F ● | P ● | F ◒ | X ⊗ | X ⊗ |

|||

| Pressure drop Hight Low | G ◒ P | G ● F | X ● G | G ◒ G | G ◒ F | G ● G | X ● F | X ⊗ G |

|||

| Coolant Liquid Gas Boiling | G G G | G G G | G G G | G G X | G G X | G G G | G G G | G X X |

|||

Figure 1 Preliminary condenser selection chart for total condensation

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here