Navigation by alphabet

A B C D E F G H I J K L M N O P Q R S T U V W X Y ZIndex

Types of Evaporators

DOI 10.1615/hedhme.a.000270

3.5.2 Types of evaporator

R. A. Smith, P. D. Hills

The standard types of shell-and-tube heat exchanger are described in Section 4.2, using the nomenclature of TEMA. More elaborate designs are usually necessary for evaporators, as described in this section.

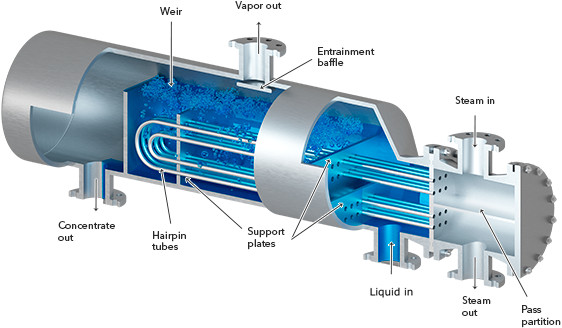

A. Horizontal shell-side evaporator

The TEMA type K (kettle boiler) is often used as a reboiler for a distillation column; it can also be used as a concentrating evaporator, as shown in Figure 1, provided that there is no danger of scaling. It may also be used as a vaporizer; the concentrate outlet can be used as a continuous purge. The liquid level in the shell is usually arranged to be just above the top row of tubes. This can be done either by using a weir, as shown in Figure 1, or by some other means of level control. Depending on the circumstances, control may be effected by adjusting either the feed to the vaporiser, the purge rate, the operating pressure or the heat input. Measurement of the level in the boiler is not always easy. The fluid in the region of the bundle is a two phase mixture with a foam level above the bundle. It may be necessary to measure the level in a calming zone removed from the bundle region.

If the liquid to be vaporised is clean and contains no dissolved solids, the weir and continuous purge may be omitted, but a drain connection must then be added to the bottom of the shell for occasional purging. Measurement and control of the level as described above will be necessary in this case.

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here