Navigation by alphabet

A B C D E F G H I J K L M N O P Q R S T U V W X Y ZIndex

Arrangements

DOI 10.1615/hedhme.a.000271

3.5.3 Arrangements for thermal economy

R. A. Smith, P. D. Hills

This section deals with steam economy in evaporators. An evaporation system converts a dilute solution into a concentrated solution or solid phase together with recovered solvent. The theoretical minimum energy required for this process is equal to the difference in total energy of the initial and final streams, which is the heat of dilution or solution together with any sensible heat due to the difference between feed and product temperatures. The energy usage of a conventional single stage evaporator is much greater than this, largely because, in such a simple arrangement, the latent heat of evaporation of the solvent is wasted. In order to improve the economics of the process, many evaporation plants are arranged to utilise some or all of this latent heat. This is normally achieved either by arranging several evaporators in multiple effect, as described in Section A, or by vapour recompression, as described in Section B. Further information on these topics and the calculations needed have been published in standard text books, for example Chilton and Perry (1999) and McCabe and Smith (1976). The advantages of flash evaporation are briefly considered in Section C.

A. Multiple-effect evaporation

In multiple effect evaporation, the concentration process takes place in several evaporators, or "effects" . The steam generated in the first effect is used as the heating medium for the second effect, and so on; only the steam from the last effect passes to the condenser. Thus steam consumption, ideally, is reduced by a factor approaching the number of effects. In order to maintain a temperature difference, each stage must operate at a pressure lower than in the previous stage. Consequently, the available temperature difference per effect is less with multiple - than with single-effect evaporation, so that a larger total surface area is needed. Furthermore, the actual amount of steam evaporated in each effect is somewhat less than that in the previous effect, because a certain amount of feed pre-heating may be necessary, because the latent heat increases with decreasing pressure, and because of heat losses. The reduction factor on steam use will be of the order of \(1/\mbox{n}^{\rm{R}}\), where \(\mbox{n}\) is the number of stages and \(\rm{R}\) is typically 0.75 - 0.95. The economic number of stages can be determined by balancing the saving in fuel costs against the extra capital charges. The maximum number of stages is governed by the temperature of the steam fed to the first effect and/or the maximum temperature to which the feed can be subjected, the need to maintain an adequate temperature difference across the heat exchanger of each stage in order to ensure boiling and the minimum pressure and hence temperature considered reasonable for the final stage or the temperature of the cooling water for the final condenser. Domestic salt evaporator trains having five or more effects are common.

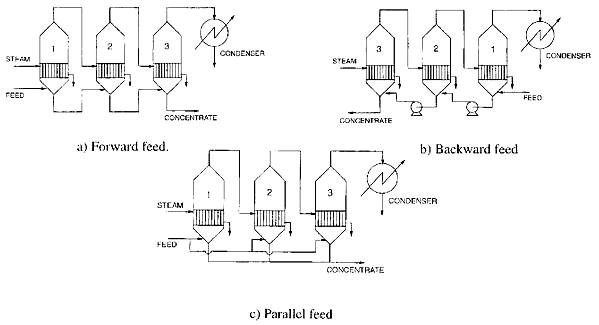

There are three principal feeding systems in use in multiple effect evaporation. In forward feed, the liquor being concentrated and the vapour produced run in co-current, parallel flow from each effect to the next, as shown in Figure 1(a). In backward feed, Figure 1(b), the liquor and vapour are in counter-current flow, and this necessitates the installation of a liquor pump between each stage, because the liquor must rise in pressure in going from one effect to the next. In parallel feed, Figure 1(c), fresh liquor is fed to each effect, the liquor entering each effect thus being at the same concentration, but each successive effect operating at a lower temperature and pressure.

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here