Navigation by alphabet

A B C D E F G H I J K L M N O P Q R S T U V W X Y ZIndex

Characteristics of Wicks

DOI 10.1615/hedhme.a.000315

3.10.6 Characteristics of wicks

D. Chisholm

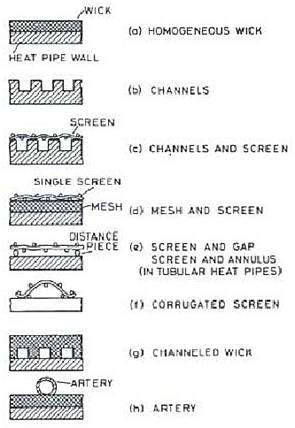

The original wick structures used in heat pipes were materials such as woven cloth, glass fiber, porous metal, and wire mesh. These wicks will be referred to as homogeneous wicks, to distinguish them from wicks made up of combinations of these materials, which will be referred to as composite wicks.

Figure 1a illustrates diagrammatically the use of homogeneous wicks. The wick is attached to the wall of the heat pipe in such a manner as to ensure good contact between the wick and the wall in the regions where heat transfer occurs. Good contact helps to maintain satisfactory heat transfer rates from and to the heat pipe wall. Channels in the wall, as illustrated in Figure 1b, have also been used: a further development is to cover the channel with a fine screen as illustrated in Figure 1c. One advantage of this arrangement is that it reduces entrainment of the liquid flowing in the wick by the vapor flowing from the evaporator section of the heat pipe to the condensing section. More important, the screen can be of very small pore size to give high capillary driving pressure without significantly increasing the flow resistance in the channels. Kemme (1966) tested the arrangements shown in Figure 1b and Figure 1c and found a threefold improvement in the performance of the heat pipe with the latter arrangement.

Some other arrangements of wick are shown in Figure 1d-h. Figure 1h is an example of a wick with an artery; the artery provides low-resistance flow paths to reduce the pressure drop in the liquid. Figure 1e-g, also provides low-resistance flow paths for the liquid.

In Figure 1e-h, the low-resistance flow path or artery is adjacent to the wall, which can have the disadvantage that boiling may occur within it. Figure 2 illustrates in cross-section some arrangements Jankers-Flutzeug-und Motorenwerke GmbH (1972) of arterial heat pipes that avoid this problem.

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here