Navigation by alphabet

A B C D E F G H I J K L M N O P Q R S T U V W X Y ZIndex

Features Relating to Mechanical Design and Fabrication

DOI 10.1615/hedhme.a.000417

4.2.6 Features relating to mechanical design and fabrication

E. A. D. Saunders

A. Barrels

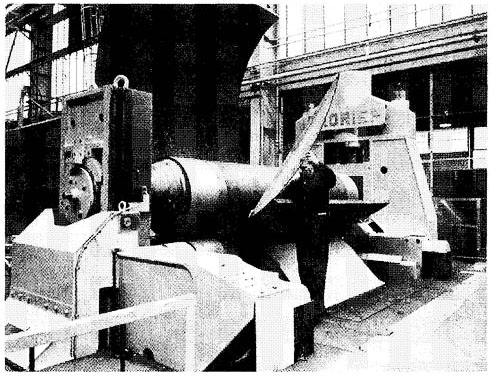

The shell barrel must be straight and have no out-of-roundness, as a tightly fitting tube bundle must be inserted into it. Most shell and head barrels greater than about 450 mm in inside diameter are rolled from plate, as shown in Figure 1, and a complete shell barrel may comprise several smaller barrels, or strakes, welded together end to end. If there is any out-of-roundness, individual strakes are rerolled after welding the longitudinal seams. The longitudinal seams of adjoining strakes are always staggered. The inside diameter of a rolled shell should not exceed the design inside diameter by more than 3.2 mm (1/8 in) as determined by circumferential measurement. All internal welds must be made flush.

When welding large nozzles to the shell, "sinkage" may occur at the nozzle/shell junction and effective measures, such as the use of temporary stiffening, must be taken to avoid it. Sinkage reduces the shell diameter at the nozzle/shell junction so that the baffle diameter must be reduced accordingly. The increased clearance between baffle and shell may result in reduced thermal performance.

Standard pipe less than 450 mm in diameter is usually available, and this will be used for the shell and head barrels instead of rolled plate. Depending on the fabricator's roll capacity, at thicknesses of the order of 80 mm and greater, or large thickness/diameter ratios, it may be necessary to use forged instead of rolled barrels.

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here