Navigation by alphabet

A B C D E F G H I J K L M N O P Q R S T U V W X Y ZIndex

Introduction

DOI 10.1615/hedhme.a.000108

1.6 SHELL-AND-TUBE HEAT EXCHANGERS (CELL METHOD)

1.6.1 Introduction

E.S. Gaddis

Single-phase multipass shell-and-tube heat exchangers provided with segmental baffles have a more or less cross flow through the tube bundle. Baffle-induced shell-side flow might influence the effective mean temperature difference and hence the effectiveness of the heat exchanger. The influence of the baffles on the heat exchanger effectiveness and on the mean temperature difference is ignored in most present thermal design calculations (see Section 106). In general, this can be justified in the following cases:

- Large number of baffles or large number of tube-side passes.

- Heat capacity rates Ċ1 and Ċ2 (Ċ = Ṁ c) of the two streams differ greatly from one another.

- Number of transfer units (NTU) is small.

More details are given in Section 118.

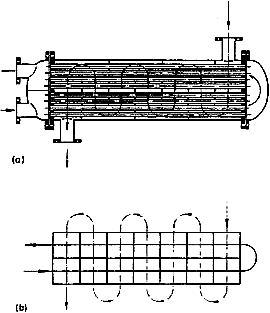

If neither of the above conditions is fulfilled, the error in computing the effectiveness of the heat exchanger due to ignoring the influence of the baffle-induced shell-side flow may not be small. To evaluate the thermal performance of the apparatus in such cases, the heat exchanger (Figure 1a) can be divided into a number of cells (sub-exchangers) coupled together as shown in Figure 1b. The background development of this method is described in References Gaddis and Schlünder (1975), Gaddis (1978), Gaddis and Vogelpohl (1984) and Gaddis and Schlünder (1976). The purpose of Section 1.6 is to illustrate with numerical examples the calculation procedure and to present rules that enable the designer to choose the flow configuration with the highest heat exchanger effectiveness.

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here