Content Map

Perforated Plate Matrix Heat Exchangers

DOI 10.1615/hedhme.a.015673

CRYOGENIC HEAT EXCHANGERS

Perforated plate matrix heat exchangers

G. Venkatarathnam

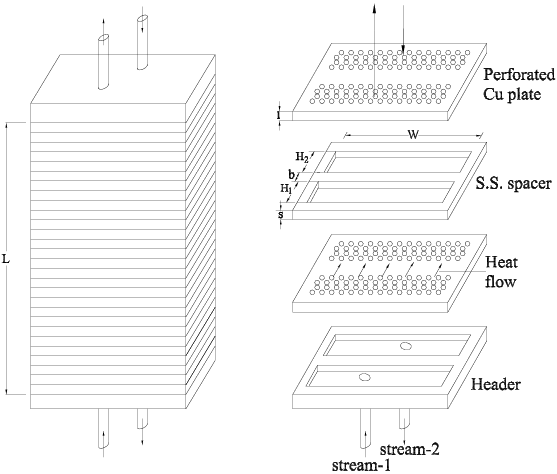

Perforated plate matrix heat exchangers, shown in Figure 1, were invented in 1949 by McMahon et al. (McMahon et al., 1950) for use in the air separation industry. McMahon et al. used a stack of perforated plates separated by rubber spacers similar to those in plate and frame heat exchangers. McMahon et al. (1950) had expected their invention to be used for large-scale air separation, but this has not happened due to the availability of reliable brazed plate-fin heat exchangers. Though the diffusion bonded matrix heat exchanger (MHE) has been proposed for use in small air separation plants (Bova et al., 1978), large-scale commercial use has not really happened.

Small MHEs are used in a variety of other applications:

- J-T refrigerators operating with mixed refrigerants (Luo et al., 2002)

- Cooling of electronic devices (White et al., 2009);

- Claude cycle refrigerators (Ornatskii et al., 1983 and Zumi et al., 1986);

- Cryoprobes used in heart surgery (Dobak et al., 2000);

- Carbon dioxide removal from air in alkaline fuel cells (Ahuja and Green, 1998);

- Helium liquefiers (Kovalenko et al., 1980).

Some of the heat exchangers used in cryoprobes are 3 mm in diameter and 15 mm in length, while those used in MEMS are even smaller. On the other hand, the heat exchangers used in helium liquefiers are about 300 mm in width and 500 mm in length.

... You need a subscriptionOpen in a new tab. to view the full text of the article. If you already have the subscription, please login here